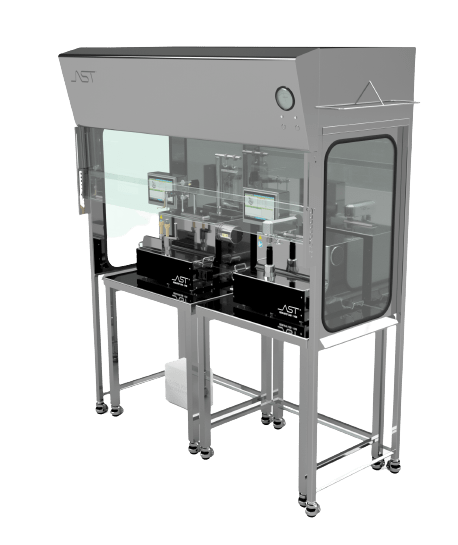

GENiSYS® Lab: Table-Top Machines for Laboratory Use & Small Batch Production

Bench-Top Filling & Closing

AST’s line of benchtop filling machines, GENiSYS® Lab, are ideal systems for drug product development and cGMP production applications. Each system is designed to automate the critical aseptic operations for vial, syringe and cartridge processing to reduce contamination risk and product variability. These table-top systems are engineered to have complete compatibility with cleanroom environments, including Laminar Air Flow Hoods, Bio-Safety Cabinets and aseptic isolators.

The Container Filling System (CFS) fills vials, syringes and cartridges and closes vials with either serum or lyo-stoppers. It can even seat press-fit caps onto the vial.

The Vial Sealing System (VSS) compliments the CFS to seal or “cap” previously filled and stoppered vials with an aluminum overseal. The VSS is also used to apply the aluminum cap and line-seal to cartridges prior to filling and closing.

The Container Closing System (CCS) inserts the piston/plunger into pre-filled syringes and cartridges using either vent-tube or vacuum processes.

Each of AST’s table-top filling machines offer the perfect balance between automated features, size and affordability without compromising quality, safety and ease of use.

Simplify The R&D and Technology Transfer Process

Developing the drug products of tomorrow requires highly flexible solutions that translate to large scale production. Each GENiSYS Lab system provides recipe parameters, system features and servo control that accurately simulate mass production operations at a bench scale. Accessing, analyzing and optimizing each process parameter is key to effective technology transfer. Each GENiSYS Lab system is equipped with ASTView, which collects all critical in-process parameter data and allows the user to export the data for analysis and optimizing. Each system can be upgraded with an Electronic Batch Record (EBR) system to provide 21 CFR Part 11 compliance.

Eliminate Hand-Filling & Risky Manual Operations

Hand filling small batch products can introduce contamination and quality risk to the aseptic process. GENiSYS Lab systems minimize this risk by automating the critical aseptic operations required to fill and finish small batch drug products. The systems enable the process steps of filling and closing containers to be carried out precisely, reliably and to meet a very high standard of quality.

Applications Include

- Research & Development

- Drug product & process development

- Small batch drug product manufacturing

- Gene & cell therapies

- Compounding pharmacies

Explore All GENiSYS® Lab

Container Filling System (CFS)

Container Closing System (CCS)

Vial Sealing System (VSS)

Ready to get started?