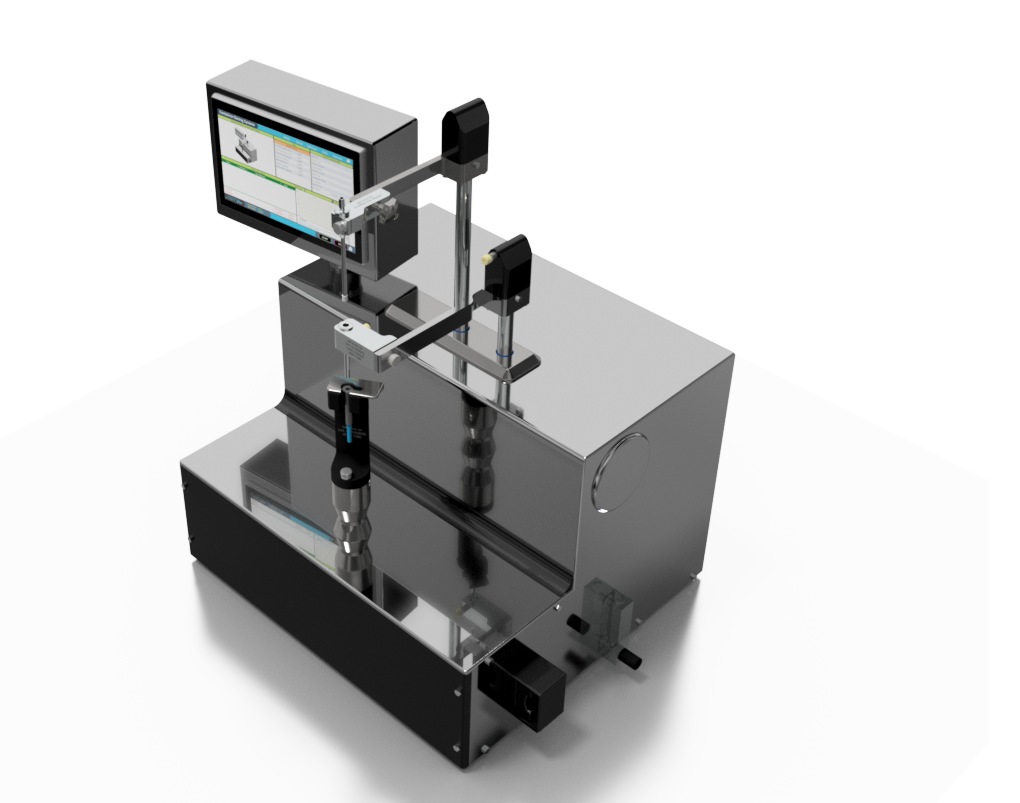

Bench-Top Syringe & Cartridge Closing System

Syringe Closing Machine

AST’s Container Closing System (CCS) is a benchtop, semi-automatic machine that provides complete and accurate control of the syringe and cartridge closing process. The Container Closing System is able to close syringes or cartridges using both vacuum and vent-tube methods for a wide range of container sizes quickly and easily with only a few format part changes.

The Container Closing System was designed with cGMP in mind. Its compact, aseptic design provides complete compatibility with cleanrooms, bio-safety cabinets, laminar airflow hoods, and aseptic isolator environments.

Given the systems process versatility and the range of container sizes the system can handle, the Container Closing System is the ideal tool for any small-batch closing machine for pre-filled syringes and cartridges.

Vacuum & Vent-Tube Process Flexibility

The syringe and cartridge closing process is electronically controlled to precisely position the piston into the syringe or cartridge under optimized conditions every time. The vacuum insertion process utilizes AST’s patented multi-stage vacuum insertion method with a mechanical assist and is an ideal option for processing silicone-free syringes and cartridges commonly used in biologic applications. Changing over the machine for vent-tube or mechanical piston insertion is as easy as simply changing out a few format parts.

Pre-Filled Syringe & Cartridge Closing Process

After the filled syringe or cartridge is manually placed onto a support, the piston is placed onto the insertion pin and retained with a vacuum. Once positioned, the machine will insert the vent-tube into the syringe or place the vacuum block on to the flange of the container. For vent-tube, the piston is inserted into the syringe, and after placement, the pin and tube are removed from the closed container. For vacuum insertion, the syringe is evacuated with a vacuum and the piston is inserted to the programmed recipe depth. The vacuum system has the added advantage of AST’s multi-stage insertion process and servo assist for ensuring the piston is consistently placed into the correct position.

Capabilities

The syringe and cartridge closing process is electronically controlled to precisely place the piston into the syringe or cartridge under optimized conditions every time. AST’s patented multi-stage vacuum insertion process evacuates the syringe or cartridge of air then gently places the piston into its final desired depth. The vacuum insertion process is the ideal closing process for biologic products that might be susceptible to long term oxidation and is the preferred approach for West CZ syringes and cartridges.

The Container Closing System provides the operator with complete control of the critical syringe and cartridge insertion process. Using the HMI touchscreen the operator is able to create recipes that control parameters such as; placement depth, placement speed, vacuum pressure for vacuum stoppering, and many other variables. All the critical process variables can be monitored and recorded with the optional Electronic Batch Reporting (EBR) system for batch documentation, process analysis, technology transfer and process optimization.

- ASTView high-resolution interface provides intelligent and intuitive control of the system for creating unique recipes and real-time process monitoring

- Motion control system provides accurate and repeatable placement of the closure into the pre-filled syringe or cartridge

- Process flexibility allows the user to perform vacuum or vent-tube insertion process on the same machine with only format part changes

- Electronic Batch Report (EBR) System records critical process information that can be used to create a 21 CFR Part 11 compliant batch report to simplify the technology transfer or regulatory filing processes

- Compact design makes the system ideally suited for aseptic isolators, biological safety cabinets or laminar airflow hood

- Clinical trial materials manufacturing

- Filling of toxic and cytotoxic materials

- Compounding pharmacies

- Stability studies

- Engineering runs

Key Features & Benefits

- Performs mechanical vent-tube and vacuum piston insertion

- Ability to process a wide range of pre-filled syringe and cartridge sizes

- Intuitive interface for easy system operation

- Fully controlled and monitored piston insertion

- Tool-less format change parts

- Optional Electronic Batch Reporting (EBR) system

- Compact system footprint allows placement within an isolator, bio-safety cabinet or laminar airflow hood

Ready to get started?

Request a consultation to get started

Technical Information

| System Dimensions (LxWxH) | 780mm x 500mm x 740mm [31" x 20" x 29"] |

| Containers | Syringes & Cartridges (Note: Tooling for non-standard/custom container formats available) |

| Syringe Sizes | 0.5mL - 50mL |

| Cartridge Sizes | 1mL to 20mL |

| Materials of Construction | Pharmaceutical grade stainless steel, plastics, and elastomers |

| Human-Machine Interface (HMI) | ASTView on a 10" color touchscreen |

| Available Closing Options | Vacuum, Vent-Tube, & Vent/Vac Combo |

| Available Options | Two-up syringe closing Pre- and post-fill container purging with inert gas Isolator compatibility upgrade Electronic Batch Report (EBR) System High speed insertion axis upgrade |